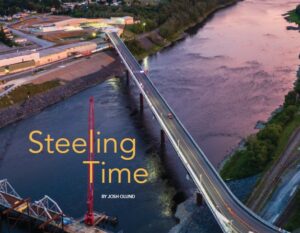

STEEL WAS THE CHOSEN MATERIAL for the original bridge over the St. John River between Madawaska, Maine, and Edmundston, New Brunswick, which opened in 1921. A century later, it was also the choice for the replacement. The Madawaska-Edmundston bridge is more than a commercial corridor and U.S.-Canada crossing. Many residents have family members on each side of the bridge. Some live on one side and work on the other. The towns share some public services, such as waste removal and emergency services. To mitigate the significant hardship a decades-long bridge replacement project would create on the area, the Maine Department of transportation (MaineDOT) implemented an ambitious campaign that allowed the new bridge to be designed in two years and constructed in less than four years.

MaineDOT partnered with structural engineer HNTB to evaluate alternatives and rapidly design the replacement bridge. After narrowing the options to a steel girder bridge and a cast-inplace segmental concrete bridge, HNTB submitted plans for the preferred alternative: a six-span steel girder bridge selected for its reduced construction risk, cost, and time savings.

Design and constructability decisions considered several factors. The new bridge site was on a steep, unstable valley with heavily fluctuating river levels. The bridge needed to be built with access through and around an active paper mill with operations on both sides of the St. John River, two independent railroad yards, and a

highly secure, active international border crossing.

The site complexity was further compounded by construction of a new U.S. Land Port-of-Entry (LPOE) facility a quarter mile upstream from its current location and a redevelopment of the Canadian Port of Entry (POE) site to align with the new north end of the bridge. All told, three major concurrent construction projects were occurring in a half-mile area.

The new U.S. LPOE location also meant the new bridge would need to be nearly twice as long as its predecessor so it could tie into the existing Canadian POE, stretch across the St. John River at a 45° angle, and connect to the new U.S. facility. Because the bridge linked two port facilities, access for maintenance would require heightened coordination from both countries. Therefore, it was specified that the new structure be constructed of durable, sustainable materials to reduce the need for frequent maintenance.

The constrained site, access challenges, and active rail yards contributed to MaineDOT’s decision to select the steel design. Weathering steel also reduced maintenance and ensured surrounding communities would have a new bridge with a 100-year service life. The new bridge is constructed with some of Maine’s longest steel girder structure spans, at 315 ft, contributing to the bridge’s longer-than-average length of 1,828 ft. It’s comprised of 3,750 tons of structural steel, nine tons of shear studs, and 972 tons of rebar.

Cost Flexibility

As the bridge advanced to final design, MaineDOT activated its contractor-in-design constructability assessment, a best practice reserved for large, complex projects. Three prospective builders provided input on project site access, staging locations, foundation types, construction risk, and project schedule, among other items.

One concern the contractors raised was how to bid the price of steel. The pandemic, which hit during the final design phase, had dried up supply chains and sent materials costs skyward. To ensure the bridge would have the necessary 3,750 tons of steel when needed, MaineDOT added a steel escalation clause to the yet-to-be-advertised contract that allowed the contractor to develop its bid based on current U.S. prices. If, at procurement, steel costs were higher than the winning bid anticipated, MaineDOT would pay the difference.

Five Foundation Types

With the contractor’s input, the design progressed efficiently and was rapidly completed. Final design began in February 2020, and by December 2020, HNTB submitted 100% complete plans for a simplified, six-span continuous structure with four variable depth steel plate girders and a composite cast-in-place concrete deck with two lanes.

The plan included five foundation designs and a foundation bid alternate for the piers. The pier bid alternates included drilled shafts and spread footings based on the bedrock 30 ft below the riverbed. Contractors were invited to bid on the foundation type of their choice, considering constructability and cost.

U.S.-based Reed & Reed, Inc. submitted a bid and won the contract in March 2021. When steel procurement time arrived, costs had escalated. Reed & Reed’s bid included five foundation types to meet the site’s conditions based on the ability to get construction equipment to each pier, construction laydown, and surrounding geotechnical requirements. Construction of the steel bridge began a month later.

All steel used on the bridge was fabricated in South Portland, Maine, thanks to MaineDOT’s negotiation with New Brunswick to include the Buy America provisions clause in the construction contract. The bridge’s I-shaped plate girders are made with AASHTO M270/ASTM A709 Grade 50W and 70W uncoated weathering steel, with the ends of the beams adjacent to expansion joints painted to avoid early onset corrosion.

For the girders over the piers, HNTB chose higher strength 70-ksi steel, which allowed for significant bending forces induced by the beams flexing over the piers instead of making the beams deeper. The stronger steel allowed the girders to be about 10 ft deep, eliminating the need for the longitudinal splicing required for deeper girders to accommodate shipping clearances.

Other steel components include connecting members, corrosion-resistant stainless-steel rebar in the bridge deck and most of the abutments, traditional rebar throughout the remaining piers and abutments, and a rare decision by MaineDOT to add steel casings around the pier columns to aid with formwork and long-term ice damage protection.

Three-Year Construction Phase

Reed & Reed crews worked on the Maine abutment through the harsh northern Maine winter in 2021–22 and wrapped up the three hammerhead piers in the summer of 2022. Canadian subcontractor Greenfield Construction finished two piers and the New Brunswick abutment simultaneously.

Crews erected the structural steel girders in late August 2022 and finished that work in March 2023. To facilitate the accelerated schedule, Reed & Reed erected its first girders in pairs, a carefully planned and choreographed process. The paired girders weighed more than 185 tons, but skilled operators and ironworkers made the two-crane lifts look easy.

Upon completion of the steel erection, crews built the forms for the concrete deck. After the deck work was completed, work began on the sidewalk, railings, lighting, and paving. MaineDOT opened the new $97.5 million six-span steel girder bridge to all vehicles in June 2024. The new bridge features wider 12-ft travel lanes, 6-ft-wide shoulders on each side, and a 6-ftwide raised sidewalk on the downstream side to facilitate the safe movement of pedestrians and cyclists. At the request of the public, aesthetic elements include ornamental railing, long-lasting LED lighting, and three flag poles to represent each country and the First Nations insignia, representing the local indigenous community that first inhabited the region.

https://tensorengr.com/wp-content/uploads/2025/02/ModernSteelConstructionArticle.pdf